KCL Power has 30 years of machinery developing and manufacturing experiences, our team can custom-made automation machinery based on your production needs to reduce labors and WIP.

PM-2013 ADV

Insole Automation Machine

WIP Discussion

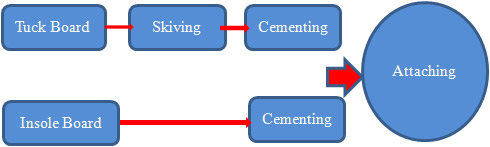

Conventional way needs 5 WIPs, which are insole cementing, number stamping, tuck board skiving, tuck board cementing, insole and tuck boards pressing and attaching.

These processes require 5 labors and 4 machines.

Mass Production

After the prototype has been field tested on mass production line in shoe factories and approved by shoe brands QC, it’s then become available

for mass orders to help shoe factories reduce labors and WIP and increase product quality and profit with standardization.