全球知名品牌adidas足球鞋之中底板作業原需要5個工序,分別是中底板擦膠、中底板鞋碼打印、中插切削、中插擦膠、中底板與中插貼合。這些工序需要用到5位勞工和5台製鞋設備。

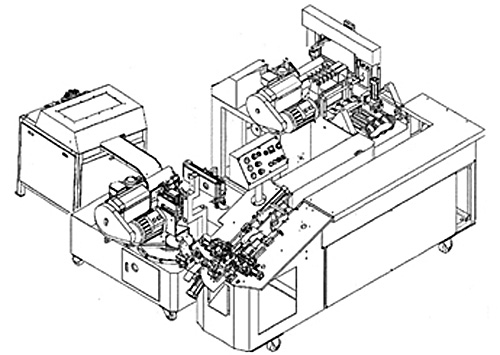

明治自動化團隊把這5個工序的時間拆解並與客戶端討論,產生一個新的替代工序和時間。產出的全自動化機器,只需使用1位勞工和1台機器來完成所有工序。

| Process | Working Length | Working Time (1pair) | Working Time in Section (1pair) | Working Time in Total (1pair) | |

|---|---|---|---|---|---|

| Section 1: Midsole Cementing | 6sec | ||||

| 1 | Feeding | 30CM | 1sec | 3.5sec | |

| 2 | Hot Melting | 30CM | 2sec | ||

| 3 | Turning | 30CM | 3.5sec | ||

| 4 | Connect to Attaching Set | 30CM | 3sec | ||

| Section 2: Shankboard Skiving | |||||

| 1 | Feeding | 30CM | 1sec | 1sec | |

| 2 | Skiving | 60CM | 1sec | ||

| 3 | Connect to Robot Arm | 50CM | 1sec | ||

| Section 3: Attaching | |||||

| 1 | Midsole feeding | 50CM | 1sec | 6sec | |

| 2 | Shankboard feeding | 30CM | 6sec | ||

| 3 | Attaching | 40CM | 6sec | ||

| Section 4: Rolling-press | |||||

| 1 | Feeding | 120CM | 4sec | 4sec | |

| 2 | LG-1122 Rolling-press | 30CM | 1sec | ||