Renowned soccer brand Adidas’ insole board process originally needs 5 working process (WIP), which are insole board cementing, insole board size stamping, shank board skiving, shank board cementing, and insole and shank boards attaching. These WIP require 5 labors and 5 machines.

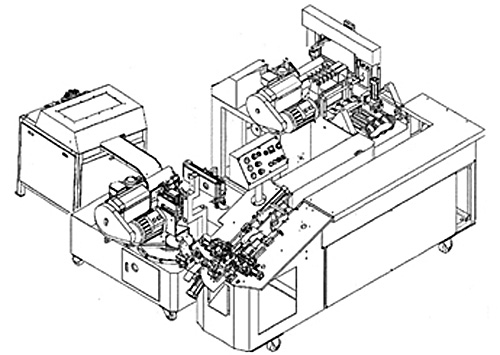

MINZ Automation Team analyzes each WIP with shoe producer to develop a brand new WIP. The result is the same product now being produced by only 1 labor and 1 machine.

| Process | Working Length | Working Time (1pair) | Working Time in Section (1pair) | Working Time in Total (1pair) | |

|---|---|---|---|---|---|

| Section 1: Midsole Cementing | 6sec | ||||

| 1 | Feeding | 30CM | 1sec | 3.5sec | |

| 2 | Hot Melting | 30CM | 2sec | ||

| 3 | Turning | 30CM | 3.5sec | ||

| 4 | Connect to Attaching Set | 30CM | 3sec | ||

| Section 2: Shankboard Skiving | |||||

| 1 | Feeding | 30CM | 1sec | 1sec | |

| 2 | Skiving | 60CM | 1sec | ||

| 3 | Connect to Robot Arm | 50CM | 1sec | ||

| Section 3: Attaching | |||||

| 1 | Midsole feeding | 50CM | 1sec | 6sec | |

| 2 | Shankboard feeding | 30CM | 6sec | ||

| 3 | Attaching | 40CM | 6sec | ||

| Section 4: Rolling-press | |||||

| 1 | Feeding | 120CM | 4sec | 4sec | |

| 2 | LG-1122 Rolling-press | 30CM | 1sec | ||